Based on years of our experiences in Oil and Gas industry, we provide various engineering services for our customer to fulfill their demands according to applicable standards, regulations and other technical specifications. We are focusing mainly on metering and regulation (M&R) in Oil and Gas industry, but these days we are proud, we can also offer to our customer the expanding services in hydrogen industry.

Project design

We provide project design at different stages according to customer needs and requirements. We ship our designs as turnkey service, starting with consultation of customer needs and ideas, through all required approvals, to customer handover and construction supervising.

Process calculation

Our process engineers are ready to verify and optimize nearly every process in Oil and Gas industry including, but not limited to pre-heating, drying, cooling, compression or expansion. Based on process calculation, other steps follows e.g. flow simulation, instrumentation selection, layout design, 3D design etc.

Flow simulations

To maximize the accuracy of metering lines designed by our company, flow simulation is used to find out any disturbances, asymmetries, backflows or crossflows in pipeline system. We use advanced simulation programs to verify the real situation in metering line, so we can predict and evaluate the behavior of metering line before the single weld is made.

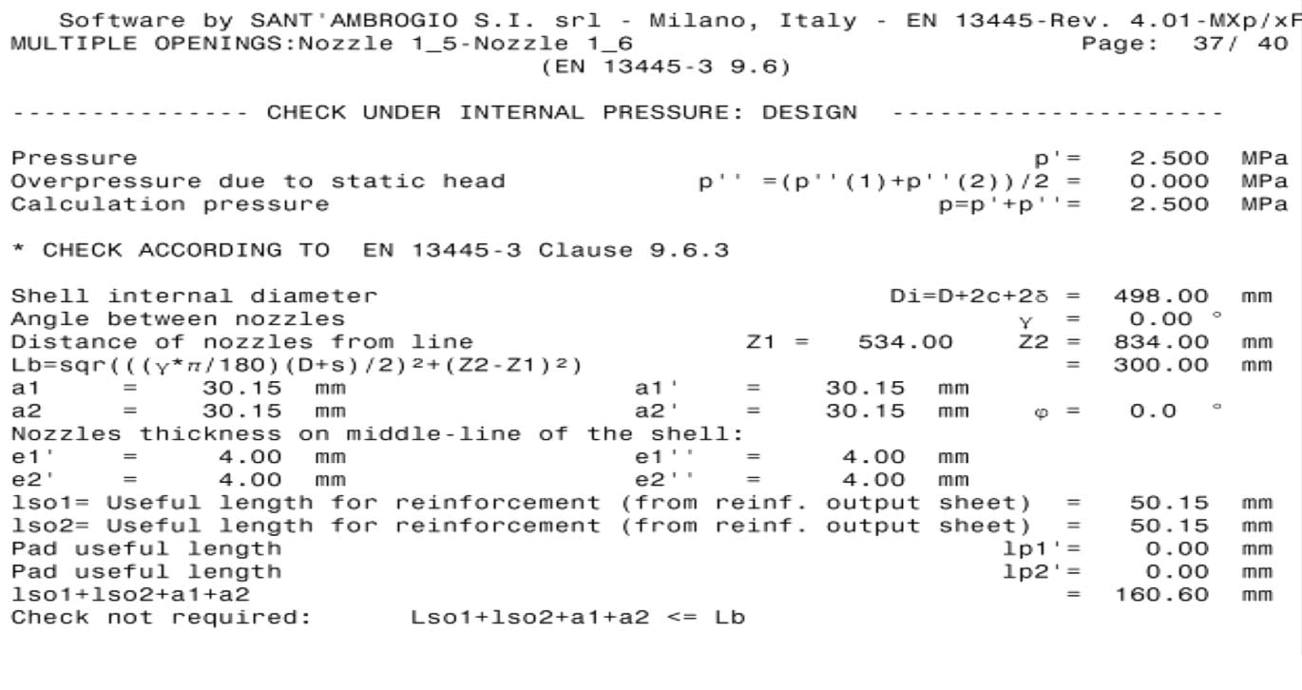

Strength & vibration analysis

Strength calculation is one of the crucial calculation when the design of any mechanical construction is made. It doesn’t matter, whether it is a single metering line or the on key skid construction, every time it is the part that have to be taken into account. It is important to know how much can designed material handle and how it will tolerate 24/7 operation. Our company is capable to design and prove the correct construction both for normal and seismic areas, including vibration analysis to prevent the selected configuration to reach the resonance frequencies during normal operation.

Engineering

| MODE | FREQUENCY (Hz) | FREQUENCY (Radians/Sec) | PERIOD (Sec) |

|---|---|---|---|

| 1 | 2.600 | 16.338 | 0.385 |

| 2 | 3.169 | 19.910 | 0.316 |

| 3 | 3.273 | 20.563 | 0.306 |

| 4 | 3.295 | 20.704 | 0.303 |

| 5 | 3.312 | 20.808 | 0.302 |

| 6 | 5.322 | 33.437 | 0.188 |

| 7 | 5.516 | 34.655 | 0.181 |

| 8 | 5.591 | 35.130 | 0.179 |

| 9 | 5.626 | 35.346 | 0.178 |

| 10 | 5.643 | 35.457 | 0.177 |

| 11 | 5.721 | 35.947 | 0.175 |

| 12 | 7.795 | 48.980 | 0.128 |

| 13 | 8.157 | 51.249 | 0.123 |